ABOUT SAGAMA

Saga Prefecture is the birthplace of Japanese ceramics.

For the past 400 years,

we have been giving aesthetics unique to Japan

a shape with tradition and innovation.

Five of our outstanding brands are now advancing to Asia

and to the world.

In 1616, a Korean potter, commonly known as Yi Sam-pyeong, discovered the ore that is used as a raw material for porcelain in Izumiyama, Arita-cho. He built a kiln nearby and fired white porcelain. This was said to be the first porcelain that was made in Japan and was the beginning of its manufacturing.

From the 1650s, ceramic ware from Saga was exported to European countries by the East India Company. It was called “IMARI” in Europe, named after the shipping port of Imari. Many European aristocrats loved these pieces for their beautiful design patterns in colors such as gold, red, green, yellow, and so on, on a white surface, along with their subtle and gorgeous decorations.

From the 1650s, ceramic ware from Saga was exported to European countries by the East India Company. It was called “IMARI” in Europe, named after the shipping port of Imari. Many European aristocrats loved these pieces for their beautiful design patterns in colors such as gold, red, green, yellow, and so on, on a white surface, along with their subtle and gorgeous decorations.

In the 1870s, Arita built up a reputation through active participation at the frequently held Expos that were happening mainly in Europe at that time.

With the popularity of Japonism in Europe, Japanese art attracted a great deal of attention and won many awards.

In 2016, Saga ceramic ware commemorated its 400th founding anniversary. Traditional potters are preserving traditional techniques, while new efforts are being made one after another.

In 2020, the “SAGAMA Project” has started to step out from Saga’s kilns to Asia and the world.

In 2016, Saga ceramic ware commemorated its 400th founding anniversary. Traditional potters are preserving traditional techniques, while new efforts are being made one after another.

In 2020, the “SAGAMA Project” has started to step out from Saga’s kilns to Asia and the world.

Arita ware is well-known for its brightly painted, beautiful designs on a well-refined white surface.

Arita ware was made for export from an early era. In response to the strict demands of Europe, it influenced notable kilns, not only in Japan, but also around the world. It established itself as a representative of Japanese porcelain.

In the 400 years since then, the production of Arita ware is now varied from tableware to arts and crafts.

Since the 1600s, there was a kiln patronized by the Saga Domain in Okawachiyama Imari where they were firing ceramic ware called “Nabeshima” to present to the family of the reigning shogun and others.

The place was called “the village of hidden kilns”, and in order to prevent the leakage of its techniques, a barrier was established in the rugged terrain.

Today’s potteries are inheriting highly-skilled techniques from the past while adopting new techniques, and have been passing down about 350 years of the history and tradition of Imari-Nabeshima ware.

Since the 1600s, there was a kiln patronized by the Saga Domain in Okawachiyama Imari where they were firing ceramic ware called “Nabeshima” to present to the family of the reigning shogun and others.

The place was called “the village of hidden kilns”, and in order to prevent the leakage of its techniques, a barrier was established in the rugged terrain.

Today’s potteries are inheriting highly-skilled techniques from the past while adopting new techniques, and have been passing down about 350 years of the history and tradition of Imari-Nabeshima ware.

It is characterized by its rough simplicity coming from coarse clay and a variety of decoration techniques.

In the world of Japanese tea ceremonies, there has long been a rating of tea bowls such as “Ichiraku (First Raku)”, “Nihagi (Second Hagi)”, and “Sankaratsu (Third Karatsu)”, and Karatsu ware has been loved by many masters of the tea ceremony as a masterpiece.

In recent years, its simple and one-of-a-kind refinement is becoming popular as tableware that enhances tea, cuisine, and flowers, and there is also an enjoyment in searching for just the right piece to hold one’s interest.

Hizen Yoshida ware is made in Ureshino City, Saga Prefecture, which is famous for the aromatic Japanese tea called “Ureshino Tea” and Ureshino Onsen, which is one of the most famous hot spring resorts in Japan.

The small area called “Hizen”, which straddles Saga and Nagasaki, is a ceramic ware production area where many kilns have been operating since the 1600s.

They have been making tableware that can be used in daily life for a long time, and have been challenging themselves to make unique products with solid foundational techniques.

Hizen Yoshida ware is made in Ureshino City, Saga Prefecture, which is famous for the aromatic Japanese tea called “Ureshino Tea” and Ureshino Onsen, which is one of the most famous hot spring resorts in Japan.

The small area called “Hizen”, which straddles Saga and Nagasaki, is a ceramic ware production area where many kilns have been operating since the 1600s.

They have been making tableware that can be used in daily life for a long time, and have been challenging themselves to make unique products with solid foundational techniques.

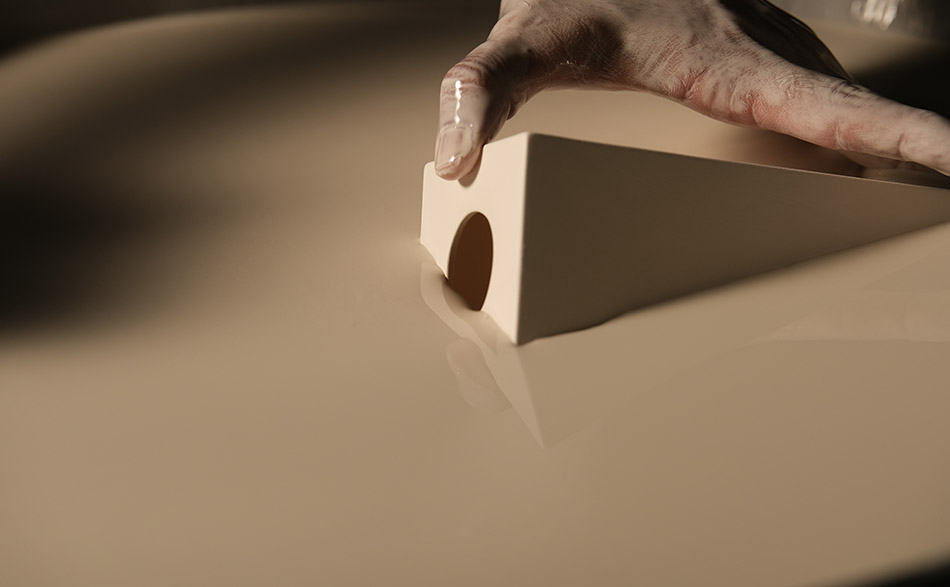

As an old saying goes, “it takes three years to master kneading the clay and ten years to master the potter’s wheel”. In other words, to mature and knead the clay is easy, but to make it right, one also needs to acquire the technique. It takes about three years to master the skills to make the clay for our ceramic ware. First, the clay needs to be matured for a certain amount of time and then kneaded carefully to remove the air and soften it.

The clay is placed on the potter’s wheel and begun to be spun. Using wet hands to cover the entire surface of the clay, the potters guide and shape it according to their movements. By concentrating all of their attention to their fingertips and continuing to rotate the wheel, the clay begins to change into the beautiful shape of tableware.

After casting and drying, the pottery is put on the potter’s wheel again and carefully planed with a turning tool to make it uniform.

After that, the pottery is fired at a low temperature of about 900 ℃ in order to reduce the shrinkage rate of the main firing and to make it easier to glaze the pottery.

“Gosu” is a paint made of natural minerals, which develops an indigo color when fired. It is also one of the oldest techniques that originated in Arita. The elaborate outline of the design pattern is painted in one go with a fine brush.

Painting inside the lines that have been drawn in a previous process is called “Dami”.

In it, a specialized thick brush is filled with paint, which is then carefully applied by squeezing the brush’s bristles, using surface tension, and inclining the product. The leftover paint is returned to the brush by loosening the pressure of the hand. It is an extremely difficult process of true craftsmanship.

Each kiln has their own way of compounding glazes.

To ensure that the glaze is applied evenly, products must be skillfully dipped in the glaze.

The underglaze becomes invisible once, but after it is fired, the glaze becomes transparent and glassy, and the underglaze design will reveal itself again as the surface becomes glossy.

Products are fired at a high temperature of about 1,300 ℃, using wood and gas as fuel.

A product called “Sometsuke (blue and white porcelain)”, which is decorated only with Gosu, is completed in this firing process.

After the main firing, paints other than the indigo colors of Gosu, such as red, green, yellow, gold, and so on, are painted on the glazed glassy surface. “Akae” is the method to overglaze on white porcelain, and “Somenishiki” overglazes on the underglazed enamel products.

In order for the paint applied with the Akae method to fix, it is fired at a low temperature of 700 to 800 ℃ in a kiln called an Uwaegama (Akaegama), which is a special kiln for firing the overglazed products.

The finished product shrinks by about 15% from the original material immediately after casting. As you can see, skilled artisans spend a lot of time and effort to carefully make each product with high-quality materials.